(Revised 20apr06).

It is reposted here as a historical reference and basis of comparison for future revisions to the O1.

Couloir began prodding telemark binding manufacturers back in 2001 to “expand their horizons from merely binding the boot to the ski, to restoring mountaineering versatility to telemark.” Based on results, several manufacturers heard that complaint. The latest to offer proof is Black Diamond, with the announcement of the O1, their freeride binding for the freeheel world.

Most modern telemark boot/binding combinations deliver a system with extraordinary downhill power and control, with inverse desirability for uphill skinning. Black Diamond’s O1 binding restores the balance of power and freedom that backcountry telemarkers require.

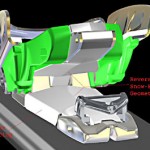

At a glance, the O1 is an O2 with a hinge beneath the toe. This simplistic description, of course, completely overlooks the actual refinement and superb elements of design incorporated into the O1.

The hinge is a 10mm diameter axle pressed into a baseplate of hot-forged aluminum. To engage the touring pivot, simply put the tip of your ski pole in the rear dimple of the toggle switch at the front of the binding and lean down on the pole, or give ‘er a sharp smack with the palm of your hand. That causes the spring-loaded latch under the rear of the toeplate to let go and the toeplate then swivels on the axle. Say goodbye to over 20 pounds of flex resistance per step (per BD’s own testing), and hello to the skinning freedom Alpine Touring skiers know and love. The location of the pivot is directly under the 3-pin line, making for a more natural stride that feels like you’re pushing off your big toe, not pivoting awkwardly in front of it.

In my first skin up using O1’s touring mode I found myself setting my own skin track as much to feel the tips float in pockets of powder as to revel in how easy it was to make kick turns with a totally free heel. With a heel this free, once you figure out how to make a snap kick-turn you may even find yourself, like me, seeking a line that maximizes switchbacks, just for the practice, and eventually the satisfaction, of being able to change direction with so little effort.

The baseplate mounts to the ski using a standard 4-hole pattern. It has a 1° angle on the front part of the plate, where the touring switch is, and also bows a bit between mounting screws to reduce the tendency for the baseplate to create a dead spot in a ski’s longitudinal flex.

Between the baseplate, which is screwed to the ski, and the pivoting toeplate, BD added a sleeve of low thermal capacity urethane that does three things:

- sheds snow due to the hydrophobic nature of urethane and it’s mating V-shaped surfaces which forces any snow out from the mating surfaces on the underside of the toeplate,

- eliminates the repeated connections of metal to metal in walk mode, and

- also dampens vibrations transmitted during ski mode. Unfortunately it does not eliminate the possibility of snow icing up the latch when conditions are prime for icing up (see below, six more paragraphs).

My remaining concern with the touring mode was the ease of engaging the heel lift. When I saw the standard wire heel bale found on other BD bindings I assumed it would require bending over to pull the heel wire up just like the current model O2’s and O3’s do. But I was wrong. BD has changed the spring tension in the heel bale so it lifts up with just the pressure of a ski pole handle lightly hooking under the wire. Ahhh.

Once you get to the top of your climb, press your ski tip in the front dimple of the touring switch, smack it down, and presto, the back of the toeplate is locked and the O1 is ready for ripping turns. The O1 is the most “active” telemark binding BD has ever produced, thanks to a cable exit point a 4.5mm further back than even the O2. Thus, it doesn’t just add touring freedom to the equation, it ups the ante in the realm of downhill performance too. Kind of like an O2 on steroids, but with the option of using a light touch too when you want it.

Like the O2, a pair of underfoot compression spring cartridges deliver solid flex tension in three flavors; Free-Flex, Mid-Stiff, or Ridiculously-Stiff. Like the O2, the O1 fits all telemark boot sizes from Mondo 22 through 30. However, for boots smaller than mondo size 26, shorter spring cartridges are available for Free-Flex and Mid-Stiff.

Besides the change in the cable system, the toe plate is 2mm higher at the front than the back, creating almost 2° of ramp angle for faster boot flexion, and smoother tele performance. Amazingly, BD has managed to keep the effective shim height of the O1 to a lean, 30.5mm above the ski top sheet, the same as the O2. Of course, there’s a bit of a weight (234g/pair compared to the O2) and price penalty, but what’s a few grams between steps compared to 20+ pounds of flex resistance. Besides, isn’t the cost of freedom worth something?

Optional ski crampons will be available in two widths, 90mm and 110mm. The crampons will slide in to a small metal block in a fashion similar to how Dynafit crampons attach to a ski. Should the touring switch fail for any reason, the O1 is designed to revert to downhill mode wherein the toe plate is locked firmly.

Icing on the toeplate latch

Like the Targa Ascent, we have noticed that when the conditions are right, the latch holding the back of the toeplate down for turning mode can ice up. This can make it difficult to switch from Touring Mode to Downhill Mode without requiring a bit of fidgeting. In our experience (about 10 days in the field so far) these are the same conditions that can cause climbing skins to ice up, cold snow and warm temperatures. Most of the time all you need to do is stomp your foot down extra hard to break the ice free so the latch latches. However, I’ve also been forced to take my boot out of the binding and chip the ice away with a ski pole tip, or other metal instrument (a Leatherman). Even after all that, in one case, it still didn’t want to latch without smashing my foot down repeatedly. I couldn’t see what was causing the hang up in this case, but it did cure itself eventually.

Although this was frustrating at the time, it does not diminish the value of having the free pivot. I’ll take an occasional hiccup like a latch icing up (when conditions are ripe for it anyway) over going back to touring with a high tension cable.

Now if you’re wondering why a touring binding, and not one with release, that’s simple. Touring is a feature that was achievable in a relatively short time frame. The O1 has already seen one season of testing abuse, and 200 pair of production bindings will see another season of use before the final product reaches retail shelves in Fall 2006. If you haven’t been impressed with the current releaseable offerings for telemark, neither has BD. Reliable release in telemark mode is, to repeat, not a trivial equation to solve. Development of that feature is ongoing, but the time frame for when anything worthy might available is still up in the air. Better to deliver what can be improved, than wait forever for the Tele Grail.

This is a rerun of an article originally published on Couloir Online 22dec05 (Revised 20apr06). It is reposted here as a historical reference and basis of comparison for future revisions to the O1.© 2005

3 pings

[…] Posts BD’s O1 (2011) BD Introduces O1 (2006) © 2012 Share this:PrintEmailShareStumbleUponDiggRedditpinterest Posted in […]