Design of a TTS system:

How can a tech toe be strong enough to hold a tele boot?

Many people (particularly those familiar with using dynafits as an AT binding) have questioned how a Dynafit toepiece can hold the boot without a heel piece. When using the toe piece for touring uphill the boot will pop out of the toe piece if it is not ‘locked’ so how can it deal with the forces generated when skiing with no Dynafit heel mechanism?

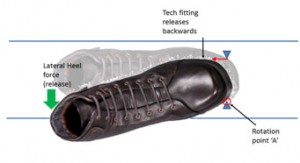

It is important to understand how the Dynafit jaws engage with the boot. The jaws, or pins, of the toe piece engage in the tech fittings (little ‘cups’) in the toes of the boot and the detail of the geometry is critical. The jaws open laterally to release the boot if the boot heel is pushed sideways, but in order to pry the toe jaw open, the tech fittings engage with the toe piece at an angle on the front, so that as the boot rotates laterally the jaws are levered open. The wall at the ‘back’ of the cup is not ramped, so the cup cannot be easily pushed forward out of the jaws. This means that if you take a boot and push the heel sideways the boot ‘pivots’ on one jaw and pulls backward out of the other as shown in Figure 1.

When used on it’s own, the toepiece releases with very little force applied to the heel. The magic is that when you add a compression spring that applies a force driving the boot forward then it stabilizes the system by driving the boot forward onto the toe piece and resisting any lateral torque applied to the heel.

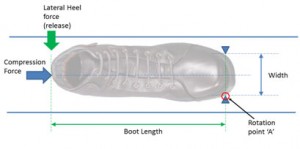

Looking at Figure 2, you can see that if a force is applied to the heel as shown, then the boot is trying to rotate counterclockwise about point A. In order for the boot to actually rotate and release then the torque provided by the heel force has to overcome the torque generated by the compression force.

So for a release the following equation holds:

Heel force X Length of boot > (must exceed) Compression force X Width/2

If the force at the heel is not great enough to overcome the compression spring then the boot will not displace sideways and the boot stays attached to the binding.

The interesting thing to note from this is that in theory a greater compression force requires a greater heel force to release the boot. This effect has been seen in some simple experiments. This shows that there is some control over the releaseablity of the binding, though in practice the forces required to get release torques greater than the equivalent to DIN 5-6 may be unrealistic to apply in practice. Note the green line shows the ‘typical’ preload on a tele heel.

Avoiding tippy toe

One of the ways in which a TTS system differs from 75mm or NTN is that the bellows are only compressed with the force that pulls the heel down from the compression springs and the weight of the skier. With no spring and no skier weight then you could rotate the boot with no bellows flex (it’s a free pivot right!). This is not the case in 75mm or NTN where, even without the spring, if you lift the heel you start to compress the bellows as a result of the front of the boot being ‘clamped’. This means that for TTS the effect of the compression spring is more critical to the feel of the binding and this has a few design implications:

- Moving the cable pivot forward / back by small increments has a very significant impact on the activity (flex resistance) of the binding.

- It is helpful to position the cable pivot lower than is typical on conventional bindings such that you get more spring engagement at low boot flex angles to replace the resistance that is lost due to the free pivot at the toe.

- It is typically necessary to have the cable pivot point further back than conventional bindings to replace the resistance that is lost due to the free pivot at the toe.

- Less active setups allow the toe to rotate too easily and the system seems to lack control

Points 2 & 3 tend to result in a binding which requires more spring travel than conventional bindings. This is discussed later.

The Mantis uses a cable pivot that is positioned 70 mm behind the dynafit toe pivot. This set up gives a feel close to Hammerhead position 3 or a BD O1. Anything forward of about 55-60 mm results in a very neutral feel. Anything rear of 80mm was going off the Hammerhead scale.

Achieving Robustness

There are 2 areas where the Mantis differs from the commercially available TTS, including the range of travel of the compression springs and the spacing of the mount.

The spring travel is an important and relatively well understood dimension of a telemark binding. As the boot is flexed and the spring is compressed, the force resisting the rise of the heel increases. At the point where the spring bottoms out there is no longer any travel or compliance in the system and the forces in the system ramp up steeply. This has two effects, the boot heel cannot be raised any further (giving a hard stop feel) and also the stress on the rear binding mounting screws can become dangerously high. In this situation, a skier driving the boot forward aggressively can lever the binding out of the ski. The Mantis avoids this situation by using the longer springs of the AXL binding which have more travel than many of the alternative cartridge based springs. This is something first tried by Ben Kadas in his AXL TTS system. The AXL springs combined with a pivot point giving a fairly active system do not bottom out and allow a ‘knee to ski’ range of motion.

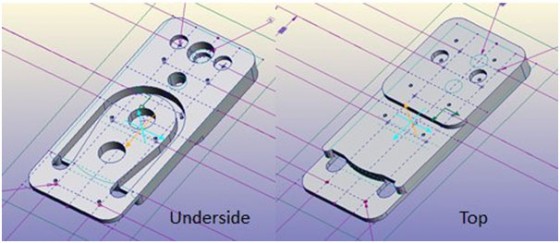

Mount pattern is also something that is of concern to any potential TTS designer. The dynafit toe never takes much torque when used as an AT binding in conjunction with a Dynafit heel. This is because any lateral movement of the heel is supported by the heel piece directly – in essence the heel and the toe work in conjunction to reduce the forces on the individual mounting screws. With a TTS system the boot is clamped into the toe piece and becomes a lever so that if the heel is pushed sideways then it applies all the applied torque through the closely spaced Dynafit toe mount. Big skis, big skiers and burly terrain could result in the toe piece being levered out. To address this issue, the Mantis does two things. First, it uses the Dynafit Radical toe piece which has a slightly greater distance between the screws. Second, rather than mounting the toe piece into the relatively soft ski, the Mantis mounts into a carbon fibre plate using inserts. This plate is extremely strong and stiff with little chance of the toe piece pulling out. The plate is then mounted to the ski, using the NTN mount pattern which has screws much further apart so that the forces for any given torque are reduced. The use of this plate and extended mount pattern reduces the forces on individual screws by approximately 3 times over a TTS system using a conventional Dynafit toe piece mounted using its standard hole pattern.

© 2012

Related Posts

BackcountryTalk thread – TTS, strength, weaknesses, workarounds

Pages:

- 1

- 2

18 pings

Skip to comment form

[…] makes it ripe for a host of DIY variations, some of which have been publicized on this website (Mantis). And Spike continues to attract interest, again, for simplicity and functionality. The biggest […]